Light Trap: Clayens Transforms the Appearance of Plastic Parts Through Surface Functionalization

Clayens has reached a new milestone in the field of plastic part surface functionalization with the development of an innovative application capable of controlling the visual appearance of surfaces exposed to varying lighting conditions. This advancement opens the door to new solutions addressing both aesthetic and functional challenges in injection-molded parts.

An Industrial Challenge Linked to the Visual Perception of Plastic Surfaces

During a recent development project, Clayens teams identified a phenomenon of localized gloss and appearance variations on a plastic part. Analysis showed that this visual defect was not related to the injection process itself, but to a thickness variation in the part design. This type of visual defect, often critical for visible parts or components with high aesthetic requirements, proved impossible to correct using conventional process adjustments (injection parameters, material selection, molding conditions).

During a recent development project, Clayens teams identified a phenomenon of localized gloss and appearance variations on a plastic part. Analysis showed that this visual defect was not related to the injection process itself, but to a thickness variation in the part design. This type of visual defect, often critical for visible parts or components with high aesthetic requirements, proved impossible to correct using conventional process adjustments (injection parameters, material selection, molding conditions).

Faced with this constraint, Clayens explored an alternative approach: surface functionalization through micro-texturing of the tooling, in order to durably stabilize the visual perception of the affected area.

Micro- and Nanotexturing to Control Light–Material Interaction

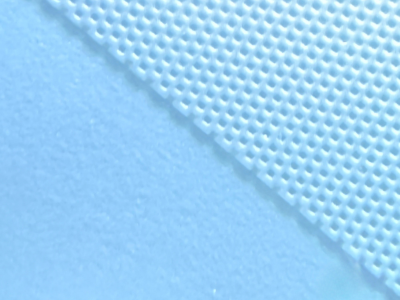

The technology developed by Clayens is based on direct micro- and nano-texturing of mold cavities, creating extremely fine patterns such as peaks, pillars, wavy shapes, or annular structures. These textures, far more precise than conventional polishing, are faithfully replicated on every injected part, without material addition, without additives, and without any post-processing treatment.

Already proven to:

- improve flow properties (1),

- reduce friction (2),

- limit adhesion (3),

- or confer antibacterial effects (4),

this technology was applied here to control the interaction between light and the surface, transforming the targeted area into a true “light trap.” The objective: to neutralize undesirable optical effects caused by thickness variations.

Design of Experiments for a Homogeneous and Stable Visual Rendering

The project team implemented a comprehensive design of experiments, comparing different micro-texture densities, depths, and geometries in order to identify the configuration providing the most homogeneous light diffusion.

The selected texture was applied to half of the mold cavity, enabling a direct comparison within the same injection cycle between:

The selected texture was applied to half of the mold cavity, enabling a direct comparison within the same injection cycle between:

- a standard surface area,

- and a micro-textured area.

The results were immediate and unambiguous: regardless of lighting conditions, the textured surface no longer exhibited any perceptible variation. The visual rendering was stable, homogeneous, and controlled, fully demonstrating the effectiveness of the light trap. This solution proved to be simple, reproducible, and fully industrializable, where process adjustments alone had reached their limits.

Industrial Validation and New Application Perspectives

Following these conclusive results, the entire mold cavity was textured, the part was declared compliant, and the mold was validated in this configuration.

This demonstration opens up new industrial perspectives:

- optical control of technical or aesthetic surfaces,

- enhancement of light-sensitive materials,

- improved rendering of visible areas,

- development of new functions based on light management and diffusion.

“This advancement clearly shows how micro-texturing can open up new fields of application,” explains Jérémy Guivarc’h, Executive Vice President Research & Development of the Clayens Group.

“By modifying the interaction between light and matter, we significantly broaden the range of possibilities offered by this technology.”

Clayens, a Pioneer in Surface Functionalization Through Micro-Texturing

With this new application, Clayens continues to push the boundaries of surface functionalization and confirms its role as a pioneer in industrial micro-texturing. This advancement marks a key milestone and opens an even broader field of exploration, with a clear ambition to go further in the next phases of development.

Parts incorporating this innovative technology will be presented at Pharmapack 2026, on the Clayens Healthcare booth – 4B54.

About CLAYENS:

CLAYENS Healthcare, representing the healthcare activity of the CLAYENS Group, supports industrial health players (medical devices, pharmaceuticals, and diagnostics) in the development, industrialization, and manufacturing of custom medical devices and plastic components in compliance with international regulatory standards.

CLAYENS Healthcare offers a complete service, from R&D to production, including industrialization, qualification, validation, and regulatory support.

Present in 9 countries, the CLAYENS Group has nearly 5,000 employees and 32 manufacturing sites. The Group's 8 cleanrooms are located in France (ISO7), the USA (ISO8), and Mexico (ISO7)

(1) “Conferring new properties to plastic parts using an innovative mold texturing technology?” - Date : 02/2022

Link: Conferring new properties to plastic parts using an innovative mold texturing technology? | Clayens

(2) “New Technological Horizon: CLAYENS, a Pioneer in Anti-Friction and Anti-Sticking Through Micro and Nanotexturing of Tooling” - Date : 02/2024

Link: New Technological Horizon: Clayens, a Pioneer in Anti-Friction and Anti-Sticking Through Micro and Nanotexturing of Tooling | Clayens

(3) “Mold Surface Texturing: A Physical Alternative to PTFE” - Date : 09/2025

Link: https://www.clayens.com/en/sintex-group-news/mold-surface-texturing-physical-alternative-ptfe-0

(4) “Toward A Safer Future: Chemical-free Antibacterial Plastics” - Date : 01/2025

Link: TOWARD A SAFER FUTURE: CHEMICAL-FREE ANTIBACTERIAL PLASTICS | Clayens