Custom busbar solutions to power your performance

At Clayens, we support leading players in electrification, mobility, and energy by providing tailor-made busbars that meet the highest standards of performance, compactness, and reliability.

As the true electrical backbone of power systems, our busbars ensure optimal energy distribution while meeting your design, space, and thermal management constraints.

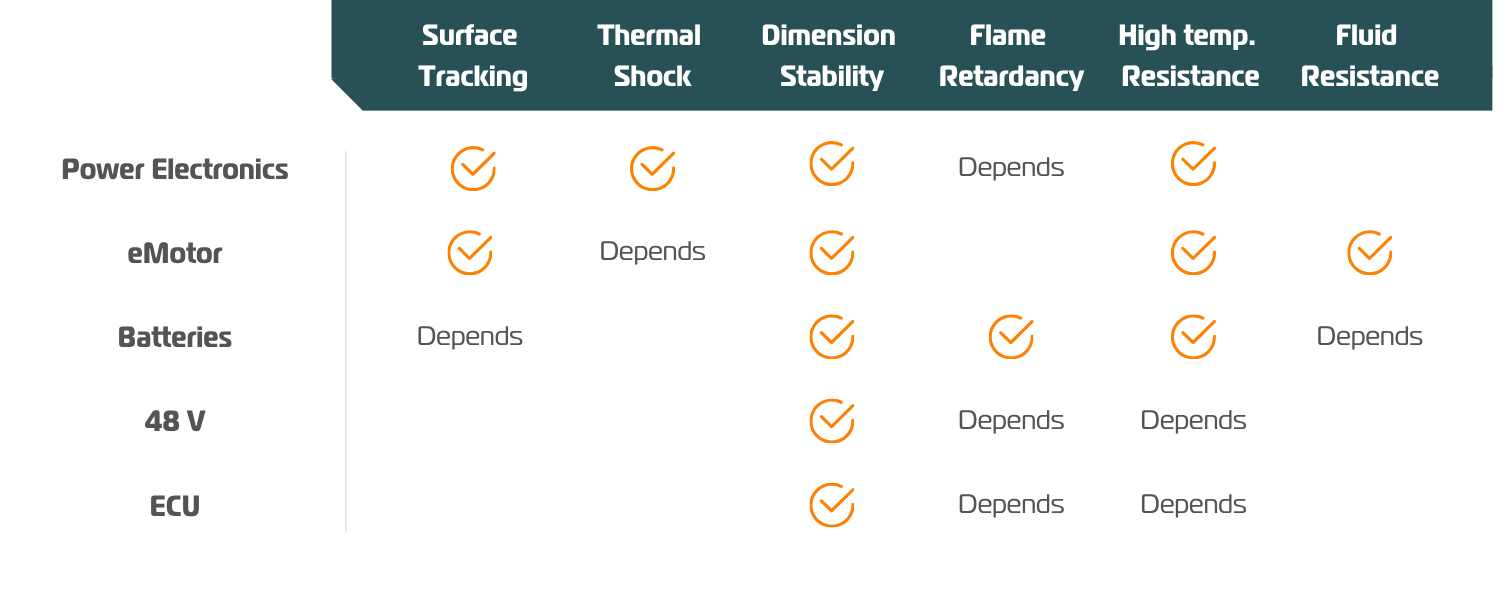

One name, different components, with different requirements...

Design & Process

We leverage our global process expertise to save time and ensure technical excellence throughout the product lifecycle. Our integrated capabilities are designed to meet the most demanding technical challenges.

Stamping, multi-sliders, strip & wire forming…

Steel, stainless steel, copper, copper alloys…

40 stamping and multi-sliders machines

450 pieces per minutes (for busbars)

100% visual inspection during stamping

Complete process definition based on the design and size of the series

High range of technical plastic raw materials

900 injection presses from 25 up to 1600 tons including 3K molding

100% electrical & visual inspection online

Definition of the quality & control level according to the customer needs & design

Online checking operations during all process phases

100% camera checking operations during stamping

100% electrical tests on automated lines

Material Selection by

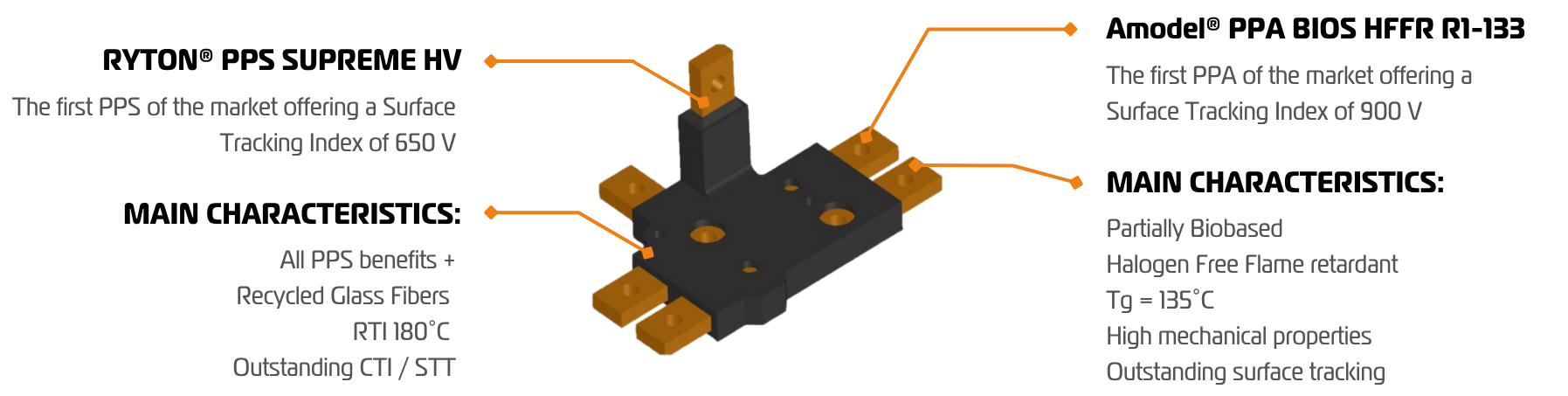

The multiplication of architectures combined with the transition from 400V to 800V and above lead to new requirements for busbars.

The multiplication of architectures combined with the transition from 400V to 800V and above lead to new requirements for busbars.

A high CTI or STT offers a high surface insulation and allows to put overmolded connectors closer. With a low CTI, those conductive parts need to be separated to avoid surface tracking and failure.

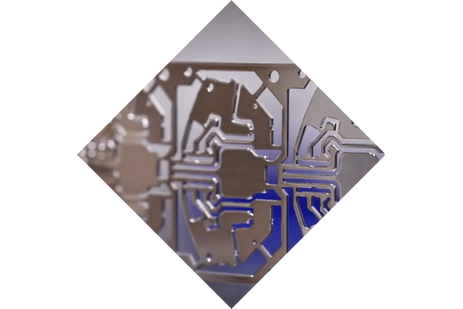

Metal-plastic parts: combining electrical and mechanical functions

Metal-plastic components are widely used, for example in high-power connectors for automotive and industrial applications.

They combine:

- Metal for rigidity and conduction

- Plastic for insulation and design flexibility

At Clayens, we manage the entire process:

- · Strip overmolding

- · Metal overmolding

- · Metal-plastic assembly

- · Injection molding with metal inserts

🤝 Technical collaboration

We recently co-organized a technical workshop with Syensqo, a global supplier of advanced materials, focused on high-voltage busbars, to share feedback and material insights. Learn more

🌱 Moving toward sustainable solutions

We also work on recyclable materials and more responsible processes, aligned with our CSR commitments and our ambition for sustainable performance. See the score